Refilling Vintage Plotter Pens

All of the vintage pocket computer plotters I am familiar with use an Alps mechanism. Some plotters might have used a different size (width) Alps mechanism, but many work the same or in similar ways.

The challenges getting these plotters working again is varied. There are cracked pinion gears, broken springs on anti-backlash gears, and consumables such as paper and pens.

There has been some great work done by others in the hobby which keeps these devices going.

One thing in common with all of these Alps plotters is the pens. These pens came in four colors: black, red, green, and blue. The plotters would have each color pen loaded in the pen carousel and this allowed for prints to use up to four colors.

Needless to say, most of these pens are likely dried up by now. On occasion you can find a working pen or revive one. However, eventually even working pens will dry up.

My First Plotter

My first exposure to these plotters was with the PC-2. I did not realize these printers were actually miniature 4 color plotters. I had thought they were dot matrix impact printers I would see on other calculators at the time.

When I first got my PC-2 plotter working, I quickly realized that the working pens that came with the printer will eventually run out of ink.

The PC-2 plotter uses the same or similar Alps plotter mechanism that many other plotters used at that time and for several years afterwards. Commodore, Sharp, Casio, Atari, Radio Shack and others used the same pens for their plotters since they all had similar Alps mechanisms.

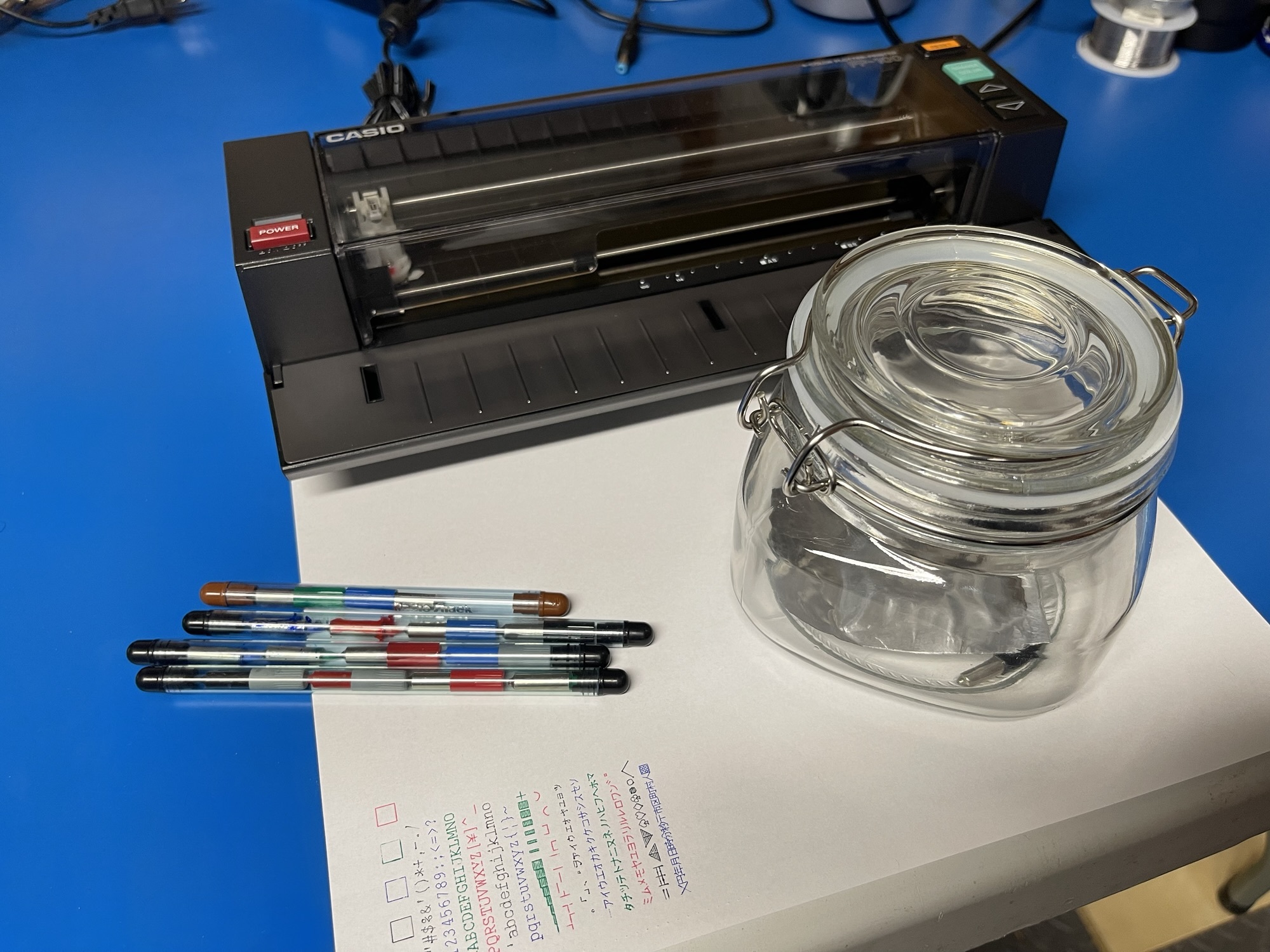

I was lucky to have had two working pens, a black pen and a blue pen. As I would acquire other models or when purchasing additional plotters for parts, I would on occasion find more working pens. More often than not, these pens would be dead. I would toss them into a container and save them anyhow.

After the PC-2 plotter, I started experimenting with the Casio variants, such as the FA-10 (for the PB-700 and PB-770) and the full page FP-100 for the PB-1000.

New Replacements

There is one source I have ordered pens from which are new. However, these are not built the same way. They are all plastic:

The plastic replacement pens work well in all of the plotters I have, except for one: the Casio FP-100. The reason for this is due to the shape of the top of the pen. Because the FP-100 pen carousel is oriented vertically, it rotates the pens directly with a worm gear. It can do this at any carriage position, unlike the horizontal oriented carousel plotters which would smack the carriage to the far left to switch pens.

Due to this updated design on the FP-100, the shape on the top of the pen is more important to the smooth operation of the carousel rotation. In my case, switching pens on the FP-100 would often cause a jam with the new replacement pens. I suspect the shape and plastic-on-plastic friction is the culprit here.

Even if the new replacement pens worked in the FP-100, the other issue with them is they are very expensive and eventually these too will dry up.

An example of most of the other plotters I have is shown below, where the pen carousel is horizontal. The replacement pens work well in these plotters.

In order for the plotters with this style carousel to change pens, it needs to move the carriage all the way back to the left. This slows down printing time, unless you optimize your printing by strategically changing colors.

Reviving Pens

In many cases it is possible to revive a pen that was somewhat sealed inside its holder with the cap on. This assumes the pen was not used much or not at all.

When attempting to revive these pens, I use no pressure at all when writing with them. The rollerball seems easily deformed or damaged on these.

I start by soaking the pen in warm water until I see some ink leaking out. I then carefully roll the pen tip over a wet paper towel and leave it in an upright position for a few days.

Never use a lighter, flame, or heat gun to try to get these pens working – you will surely melt, deform, or otherwise damage it beyond repair.

If the ink in the barrel is dried up, these methods will not work. The pen will need to be refilled.

Different Versions of the Pens

There seems to have been two iterations of these pens. One was a solid metal tip design, and the other (more common) was the plastic tip design. Needless to say, the plastic tip design seems like it can be easily damaged.

It seems the all-metal tip design was older, and at some point the plastic tip design replaced the metal tip design. It also seemed like the plastic tip design drew a more fine line compared to the all-metal tip design.

Rollerball versus Ballpoint

I am not a pen expert and there must be differences between these two types of pen tips. I needed to research a bit to determine how each works and their pros and cons.

After some interwebs searching between rollerball and ballpoint pens, it would appear they are quite different. First, their appearance is different (the tip) and the type of ink is different.

It would appear that ballpoint pens use an oil based ink, and rollerball pens use a water based ink. Ballpoint pens require a bit more pressure to write on paper, while rollerball pens require less pressure. The latter could “bleed” more on paper due to the less viscous ink used in them.

It would then make sense that the plotter pens would be rollerball type rather than ballpoint. This would require less pressure and better absorption by the paper. Further, the ink would seem to flow easier without requiring a pressurized reservoir.

If I look back at the two types of vintage plotter pens I have, most are rollerball. Only one is a ballpoint. If my assumption is correct, I need a water based ink to refill the rollerball plotter pens.

Ideal Solution

These pens have not been made for decades, and the only knock-off pens made today are quite expensive (and available from only one source). The ideal solution would be to be able to refill the original pens.

I have seen only one video discussing this being done (the video creator did not show the actual process), but when I attempted it, I ended up bending and breaking several pens. It was a bust.

Only pens which have a working rollerball are a candidate for refilling. Of course, sometimes you cannot easily tell if the ball is seized or damaged until you refill the pen.

Successful Approach

The tip of most of my pens are the rollerball version. Pliers would easily crush the plastic tip, so I did not even attempt that method. After all, I accidentally bent the metal shell on my previous attempts.

What I sought out was a method to grab onto the plastic part near the metal shell somehow and pull it away from the shell.

I thought that a chuck on a drill would be the closest thing that would grab the tip in a uniform way and with adjustable pressure. However, I needed something much smaller.

I thought a hand drill would work, since these are small, and have a chuck-like gripper for the drill bit.

I found a specific model which has a circular shaped collet which would grip all of the surface area of the pen tip, allowing for a greater chance of successfully pulling the tip from the shell.

Method of Extraction

Since almost all of the pens I have are the rollerball tip, I want to be extra careful not to damage them. This means I want to avoid crushing them with too much pressure. I also want to avoid damage from twisting the tip.

I used the small hand drill to grab the base of the tip, and a small craft vice with plastic clamping blocks to prevent damage to the metal shell.

I was able to remove the tip from the rollerball pens using the small hand drill chuck.

I placed my fingers on the hand drill where it met the vice and slowly pressed the hand drill backwards with my fingers.

The tip came right out, exposing the sponge inside the metal shell and the sponge which draws ink to the rollerball tip.

The method I used was just enough pressure on the vice to keep the metal shell in place and just enough pressure on the plastic tip with the drill collet. If I saw either slipping, I added a very small incremental amount of pressure as needed.

I did end up slightly deforming the metal barrel on a pen by clamping down on it too much with the mini vice the first time I did this. Luckily this did not affect the usability of the pen.

Type of Ink

I am no expert or even a novice at types of ink. I assume the ink in these rollerball pens originally is not exactly the same as a regular ballpoint pen ink. It would seem the original ink was water based, not oil based.

Pens that were weak or inconsistently printing have a better success rate. Pens that will not write at all are a gamble, but worth the attempt.

The tip on the rollerball version of these pens appears to be ultra fine. The ink must not be too viscous (like regular ball point writing pens would be).

I chose self inking stamp refills. These are available in a package of 5 colors, 4 of which I need.

This type of ink is water based, and certainly does not dry very quickly when exposed to the air (stamps are not exactly air tight). My thought is this ink will be less likely to dry up inside the pen.

I added a few drops to the sponge inside of the metal shell and waited for it to soak in before adding the next drop of ink.

Cleaning the Tip

In every case, I cleaned the tip in addition to adding more ink. In order to clean the tip, I took the tube-like sponge out of the tip (it is removable). I then cleaned it off with a little water, removed any debris, and then soaked the tip (without this sponge) in hot water for a few minutes.

Then put the tube-like sponge back in the tip, added a little bit of ink to it and tried the rollerball to see if it was getting ink. If it was not, I repeated the cleaning. If it did, it was a success!

I suspect there is usually dried ink in between the sponge and the rollerball that is dissolved by soaking in hot water.

I put the tip back in place using the vice and my fingers. I left the metal shell in place in the vice where it was during removal of the tip. I then lined up the tube-like sponge to the hole in the sponge inside the metal shell, and used my fingernails to press the tip back into the shell. I used my fingernails to press against the flat top part of the base of the tip until it was about a half millimeter from the top of the shell.

Never press the tip back into place with pressure on the rollerball as this can damage the pen.

Note that the tip should not be pushed to the point where the base of the plastic is below the metal rim. In fact, I found that a slightly raised surface works best:

I suspect the length of the pen needs to be perfectly matched to the printer push bar. It pushes the pen forward (or down on the vertical carousel models), and if the pen were slightly too short, it will not imprint on the paper.

The first few refills I performed I had pushed the tip too far down into the shell and while it tested fine when writing with it, it did not print when in the plotter.

I also noticed quite a bit of the ink is pushed out of the pen when replacing the tip, likely due to air pressure from pressing the tip in and a slight overfilling with ink.

There are what appears to be two small channels in the plastic tip to allow for air pressure to balance. If any extra ink added does not absorb into the sponge, it will leak out. Eventually this stopped on its own after some of the ink is consumed.

I recommend using a pair of “exam gloves” when handling the ink and pens, as it is not easy to clean ink off the fingers.

Testing

Several of each color pen was successfully refilled. I first tested a few refilled pens in my FA-10 since I had that out of the box for another project.

Note that the type of paper makes a difference in printing. Some paper will have spots where the ink will not transfer. Other papers have a more uniform surface ideal for these types of pens.

The picture above illustrates this. The paper on the left is basic Amazon copy paper, and the paper on the right is easel paper. It would appear that the Amazon copy paper works better.

I tested some pens on the FP-100 also, with great success!

Pen Storage

Storing the pens properly when not in use is important to extending their life. According to rollerball pen storage recommendations, storing the pens horizontally will reduce the likelihood of ink leaking from the pen.

The pen caps are not necessarily air tight, but they do protect the rollerball. In addition to capping each pen, they should be stored in an airtight container, preferably one which is as small as possible. The original containers are best, and those are reasonably air tight, provided you have the caps for both ends.

Obviously the pens should not be left in the plotter, but I have seen many plotters with pens still in the carousel (along with batteries left in the pocket computer).

Final Thoughts

I am glad I kept all of the pens and cases I had acquired with these plotters, whether they initially worked or not. Now that I was able to refill them, I can squeeze a bit more life out of them and these plotters.

I am not certain how often I can refill these pens before something else wears out, such as the rollerball for example. However, I am glad I gave it a go, and had some initial success.

This first test does not necessarily indicate success in the long run – time till tell how long the refill lasts for, if they dry out too quickly, if there is a better choice of ink, or other unknown variable.

However, with some reading, inspecting, guessing, and trial and error, I might have just solved a long standing issue I have had with these plotter pens.

I have been watching auction sites for deals on either the pens themselves or deals on plotters which appear to include a set of pens. Many times there are plotters sold for parts and/or junk, and extra pens are a bonus.

I will update this post as time passes with long term results of this refill experiment. I have yet to find a resource, video, or specifics from others on refilling these pens, only generalized advice or suggestions. If you have experience with refilling these pens or suggestions for improvement, contact me.